How to Really Save Electricity

My neighbor doesn’t leave his porch light on at night. I do because it’s dark in our neighborhood. It’s a security measure and just feels nice. He says he’s saving electricity and it makes me wonder - how much can it cost to keep my porch light on at night? After consulting my utility website, I found that lighting on average uses the least amount of electricity while heating & cooling amount to over half the energy used for a typical home. Turns out a couple LED bulbs costs me three cents to leave on all night.

I’ll be leaving them on and giving some spare change to my neighbor.

A little bit of security for very little cost. (image credit: Adobe Stock)

Now, I’m willing to spend a few pennies to keep the lights on. But what if it was costing me a few dollars every night? Would that change my mind? Would I look for a way to reduce that cost while still having that sense of security? Our customers need the security of an engine heater operating 24/7 to maintain startability. Reducing energy consumption of the heater was a challenge we encountered way back in the early 2000s.

Back then, an engine manufacturer needed a heater for a new engine design. An existing product could meet the need, but the customer wanted changes. So, our team sat down and worked through the requirements. How could we provide an efficient heater at an acceptable price that still provided the security expected by our customer? We had already proven the exceptional performance of pump driven heaters for larger engine applications. Applying this concept to a smaller heater design could produce the same result.

As it turns out, we had considered the idea of incorporating a pump into existing heater designs years earlier. In the late 90s, the castings for our traditional heaters were redesigned with the forethought of adding a pump with some minor modifications. This was the path we took on the project and the design we developed was accepted by our customer. Success!

One of the first Hotstart thermosiphon tank heaters fitted with a pump to improve performance.

Fast forward a few years, and we were ready to bring these smaller pumped heaters to a wider market. We had found working with the original customer that the pumped heaters had reduced their energy usage by around 30%, a benefit they promoted to their customers. They also saw better performance with the reduction of energy use. Energy efficiency wasn’t quite top-of- mind at the time, but we wondered - are there customers who would be ready to adopt the potential for energy savings? We did our own field testing to make sure the savings were real and confirmed the 30% reduction. It was obvious, way back then, that an energy efficient engine heater could amount to a lot more than a few cents a day back in the pocket of our customers.

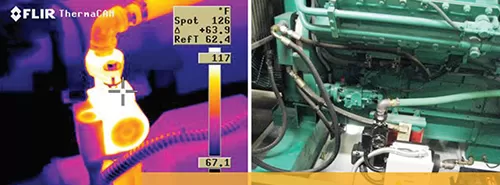

Use of infra-red cameras during field tests of pump driven heaters show outlet temperatures lower than typical thermosiphon heater outlet ports.

We released the heater and continued to improve the design that evolved and became the HOTflow product line. We continue listening to our customers and developing the best innovative solutions for their needs today, and tomorrow.