Manufacturing and production sites often include many volatile fluids, gasses, and powders that are hazardous if not properly contained or controlled. Hotstart's hazardous location equipment solutions meet the rigorous standards for certification. Our line of compressor and engine heating systems helps keep natural gas flowing as midstream operations compress and prepare the gas for processing and distribution. In cold climates, Hotstart heating systems ensure immediate startup in freezing temperatures. In warm, humid climates, Hotstart systems maintain equipment above the dew point, eliminating temperature variation that causes condensation in the oil pan and compromises the oil’s lubrication properties. Ensuring equipment is available and the system is ready is critical to reducing expenses and improving the bottom line.

Hazardous location equipment is found in a range of environments and applications. Our experience meeting certification requirements, including IECEx, ATEX and UL C/US, allows Hotstart to adapt engine heating solutions to customer specifications for process heating, heavy machinery, and other industries.

Applications

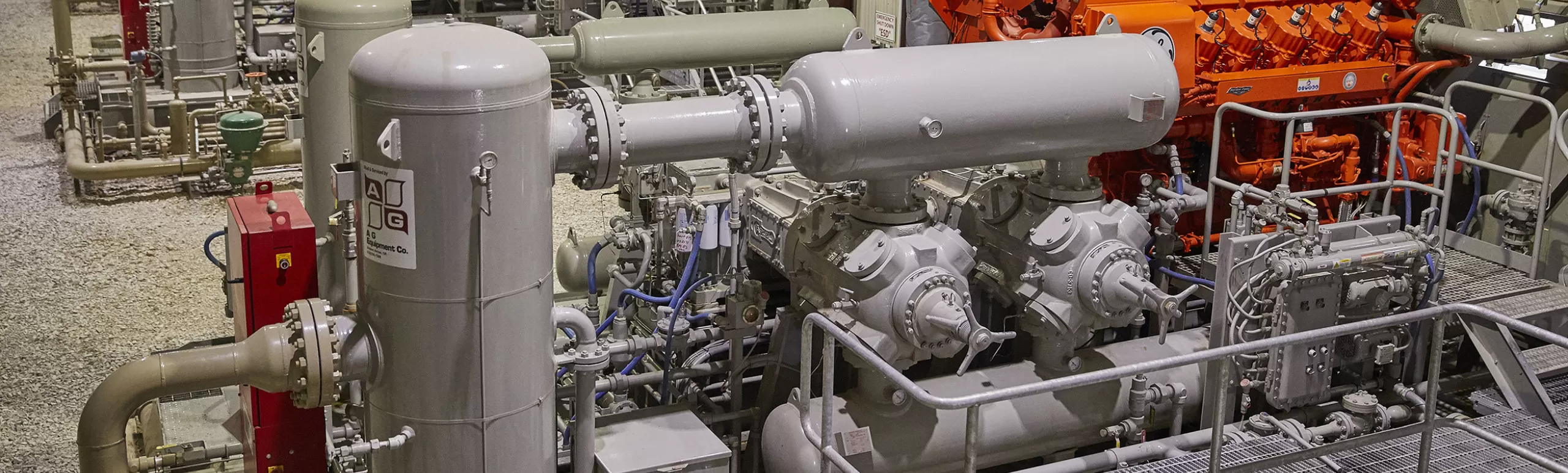

Natural gas remains an important part of the overall power generation landscape. Gas compression equipment operates best when kept at optimal temperatures. Compressor prelube systems maintain oil viscosity by generating consistent heat and circulating it through the compressor frame. This equipment ensures natural gas moves from the field to the consumer in a cost-effective manner.

Engines in hazardous locations play a vital role in providing power for gas compression operations where downtime is simply not an option. Extreme cold can prevent engines from operating efficiently, slowing production and costing money. Heating and circulating the coolant, oil, or both fluids while in standby mode ensures that equipment maintains optimal operating temperature, keeping the system ready to start with full-load power when needed.

Case Studies

In 2013, Lousiana Offshore Oil Port, LLC (LOOP, LLC) installed four pairs of Hotstart oil heating systems and coolant heating systems on its four CAT D3616 engines which that power large-capacity crude oil pumps at the Louisiana Offshore Oil Port in the Gulf of Mexico. The new heating systems are were part of a retrofit project on the pumping platform which is located approximately 18 miles off the coast of Louisiana, south of Grand Isle.

Download the LOOP case study to read the complete story on the benefits of Hotstart Oil and Gas heating systems.

In February 2020, Hotstart worked with engine manufacturer Caterpillar to perform compression skid field testing at their Miami Lakes Learning Center.

Download the case study to learn how Hotstart heating systems keep natural gas compressor packages and engines ready by maintaining optimal engine temperature during downtime.

Hazardous Location Engine Heating Case Study