CKM HOTflow® Engine Heater

Sectors

- Equipment

- Energy

- Engine

Markets

Product Categories

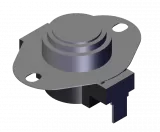

The CKM model heater is designed to be a true drop-in replacement for legacy convection-based systems. Featuring a mechanically-driven pump and a custom-designed pump volute mated to a stainless-steel tank, the CKM retains similar dimensions and options to convection systems. It can also be installed vertically or horizontally, making the upgrade to an efficient forced circulation system quick and easy. Designed for an extended operating life and peace of mind, the CKM offers access to all major operating components and includes a built-in air bleed screw and resettable high-limit thermostat.

HOTflow® engine heaters feature an integrated pump that circulates warm coolant throughout the entire engine at uniform temperatures. Constant circulation of the coolant eliminates hotspots that can deteriorate heater hoses, harm engine seals and diminish coolant life. HOTflow® engine heaters rely on fewer heating cycles - saving up to 35% in energy consumption while extending heater element life and reducing maintenance work.

Preheating diesel or gas engines ensures they are ready to start and assume full load quickly with minimal wear to critical components. Industries that rely on their engines or backup power systems to ensure day-to-day operations run smoothly, such as fleet vehicles, excavation, mining, data centers and hospitals depend on the benefits provided by consistent engine heating to maximize their equipment investment and eliminate downtime.

Not intended for hazardous locations.

Heating Information

Primary Heating

- Water

- Coolant Mix

Primary Heat Power

- 3 kW

- 4 kW

- 5 kW

- 6 kW

Power Specifications

Power Sources

- AC, Single-Phase, 60 Hz

- AC, Single-Phase, 50 Hz

Voltages

- 120

- 230

- 240

Power Connectors

- Hardwired

Temperature Control

Primary Temperature Control

- 100–120 °F (38–49 °C)

Primary High Limit Temperature

- 205°F (96°C)

Mount Types

- Bracket

Inlets / Outlets

Inlets

- SAE J1926 / 1:1 5/16-12 (#16 STOR)

Outlets

- SAE J1926 / 1:1 5/16-12 (#16 STOR)

Ingress Options

Coolant Motor Ingress

- NEMA 2

- IP44

Certifications

- CE-compliant models available

- UL-C / US recognized

Related Products

The CSM Euro features the most powerful pump (10 gpm flow) and most powerful heating element options (up to 12 kW) in the HOTflow lineup. The CSM's heating power in an energy efficient system is ideal…

The HOTflow® CSM engine heater features the most powerful pump (10 gpm flow) and most powerful heating element options (up to 12 kW) in the HOTflow® lineup. The CSM's heating power, combined with…